Transforming Modern Construction: The Competitive Edge of the CLC Lightweight Brick Production Line

In the rapidly evolving construction industry, the demand for high-quality, sustainable building materials has never been greater. Among the myriad options available, the CLC Lightweight Brick Production Line from Fujian Hamic Machinery Co., Ltd. distinguishes itself with a blend of precision engineering, innovative technology, and robust performance. This article delves into the competitive advantages of this production line and explains why it stands out from other products in the market.

Unparalleled Precision and Advanced Technology

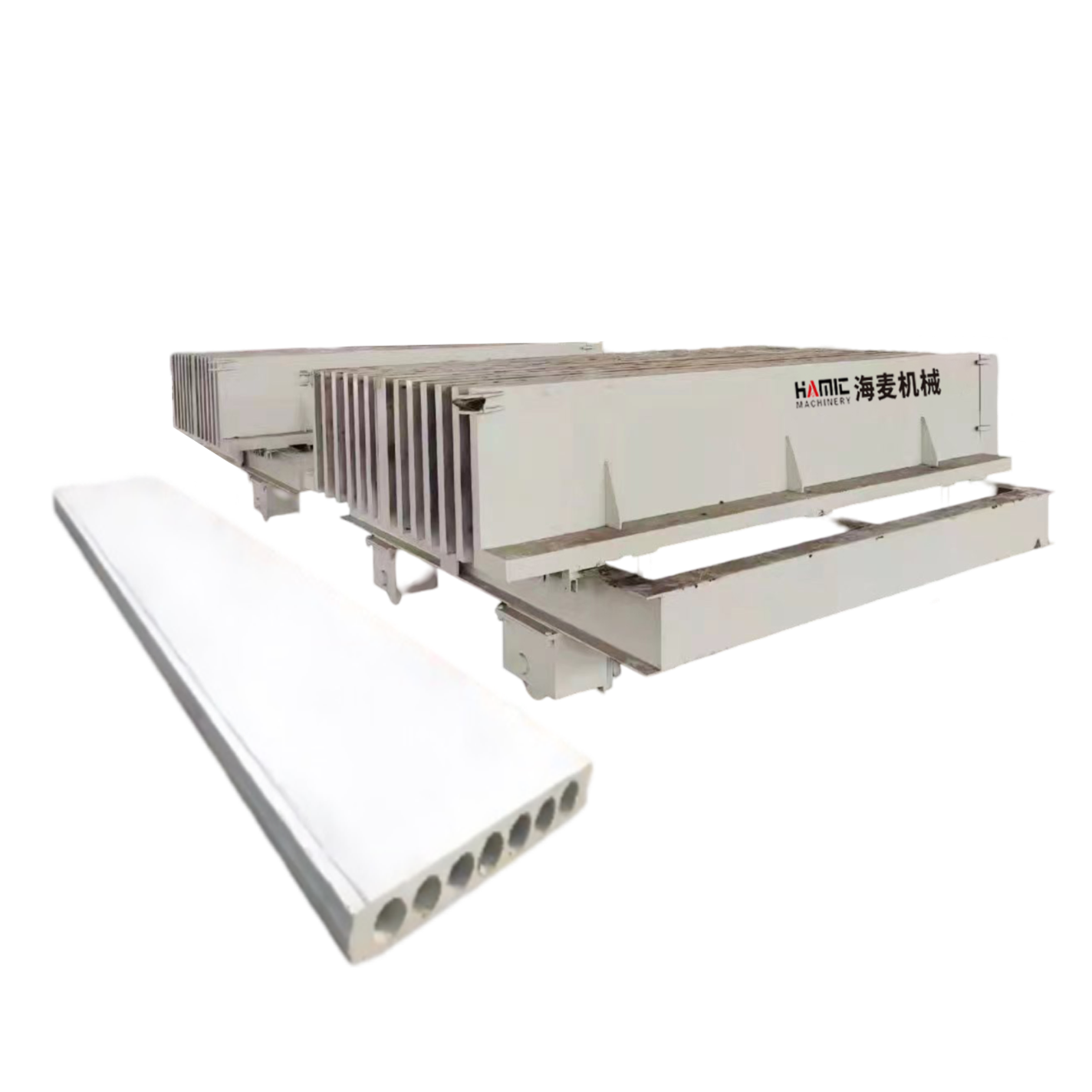

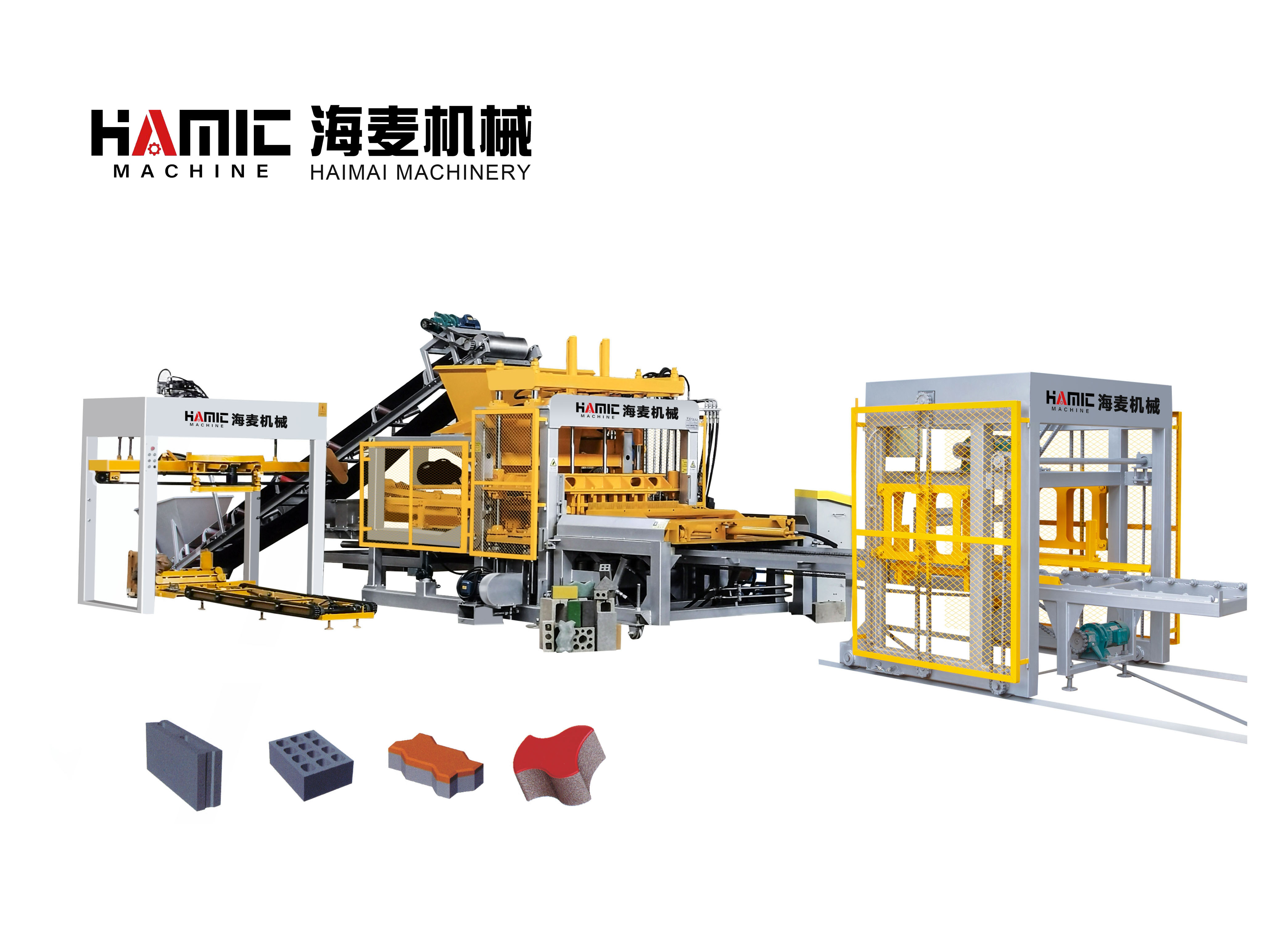

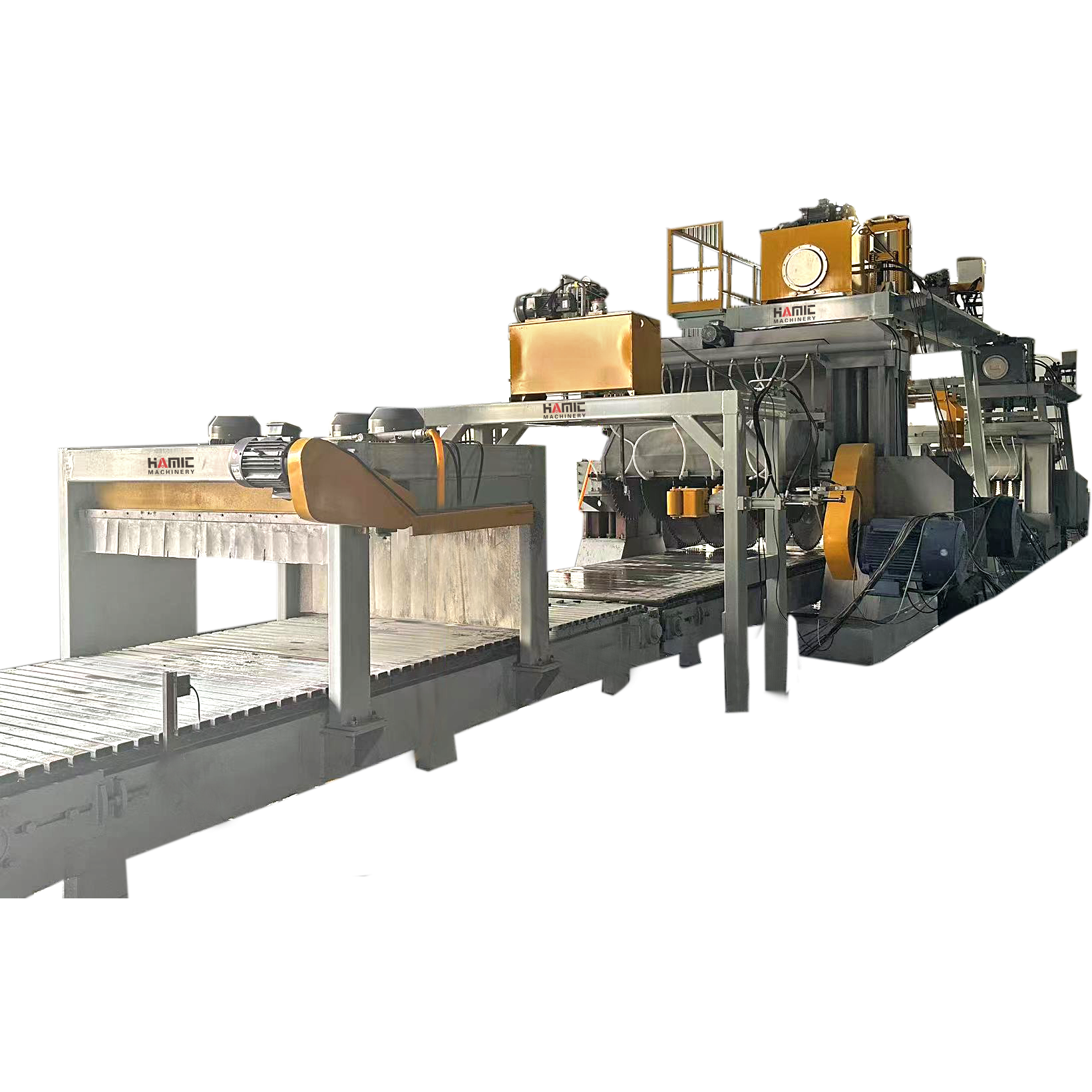

At the core of the CLC production line is a suite of state-of-the-art machinery designed for exceptional accuracy and efficiency. The CLC Lightweight Brick Machine is engineered to deliver high-quality lightweight bricks that meet the rigorous demands of modern construction. Complementing this, the Top Cutting Machine offers an advanced, high-precision solution for slicing lightweight building materials with minimal waste.

Additionally, the Single Shaft Cutting Machine and Double Shaft Cutting Machine provide cutting-edge precision for diverse production requirements, ensuring that every brick is consistently shaped to perfection. This comprehensive approach to material processing results in a production line that not only improves operational efficiency but also enhances the quality of the final product.

Seamless Integration and Operational Efficiency

Efficiency is a critical factor in today’s competitive construction market. The CLC production line incorporates an Efficient and Reliable Conveying System that optimizes the transportation of materials across different stages of production. This seamless integration minimizes downtime and maximizes productivity, ensuring a smooth workflow from raw material processing to finished product delivery.

Moreover, the inclusion of a state-of-the-art Mixing Tower guarantees uniform blending of raw materials, which is crucial for achieving superior product consistency. This holistic design underscores Fujian Hamic Machinery’s commitment to innovation and quality, setting the stage for a production process that is both reliable and scalable.

Commitment to Quality and Durability

Fujian Hamic Machinery Co., Ltd. is based in Quanzhou, a historic hub for brick machinery manufacturing in China, and has long been synonymous with quality and innovation. The CLC Lightweight Brick Production Line is manufactured in strict adherence to international quality system standards and industry benchmarks. This rigorous quality control, combined with advanced manufacturing processes, ensures that every component—from precision cutting machines to efficient conveying systems—delivers outstanding durability and performance.

Such a commitment to quality not only enhances the longevity of the production line but also significantly reduces maintenance costs over time. For modern builders and manufacturers, this means a lower total cost of ownership and a more reliable investment in technology that supports sustainable construction practices.

Economic and Environmental Advantages

Beyond operational efficiency and durability, the CLC production line offers compelling economic and environmental benefits. The precision engineering of its cutting and mixing systems reduces material waste and energy consumption, contributing to a more eco-friendly production process. Lower material waste directly translates to cost savings, making the system an economically attractive option for businesses aiming to optimize their production while also reducing their environmental footprint.

These factors combine to provide a production line that is not only ahead of its competitors in terms of technological innovation but also in its ability to deliver sustainable, cost-effective solutions for modern construction challenges.

A Proven Legacy of Innovation

Fujian Hamic Machinery Co., Ltd. has built its reputation on a foundation of continuous innovation and customer-centric service. With a comprehensive portfolio that includes self-insulating block production lines, concrete block production lines, static pressure brick machines, and even construction waste recycling solutions, the company has consistently demonstrated its ability to meet and exceed the evolving needs of the industry.

By integrating intelligent technology with eco-friendly concepts, Hamic Machinery not only enhances production efficiency but also creates lasting value for customers worldwide. This dedication to innovation and quality has cemented the company’s status as a trusted leader in the lightweight building materials market.

Discover More

The CLC Lightweight Brick Production Line is more than just a manufacturing solution—it’s a revolution in construction technology that delivers unmatched precision, efficiency, and sustainability. For a closer look at how this cutting-edge production line can transform your building material operations, please visit the CLC Lightweight Brick Production Line page.

Embrace the future of construction with a system designed to elevate your production processes and deliver superior results every time.