Mastering the Use of the QT8 Block Making Machine: A Comprehensive Guide

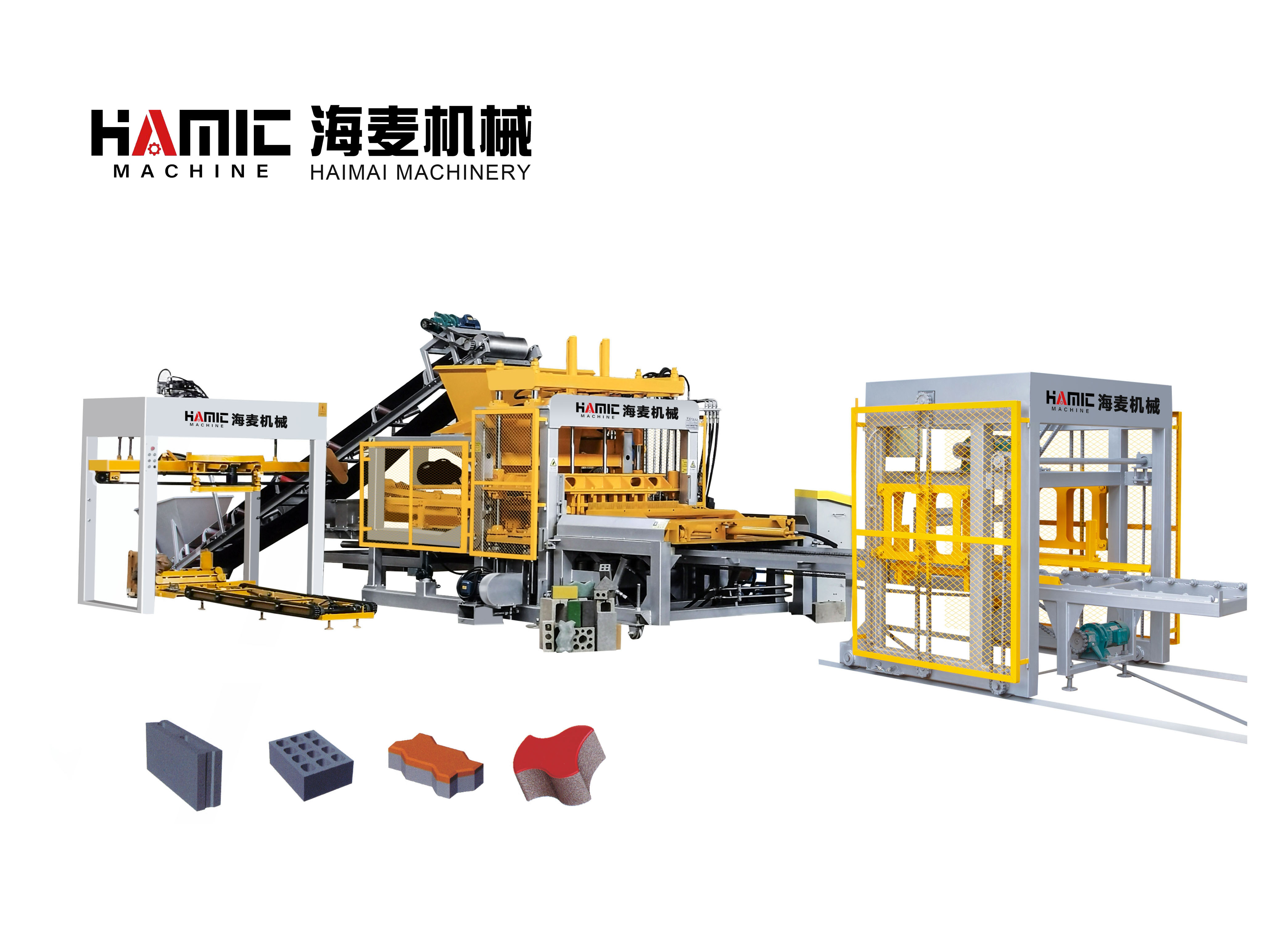

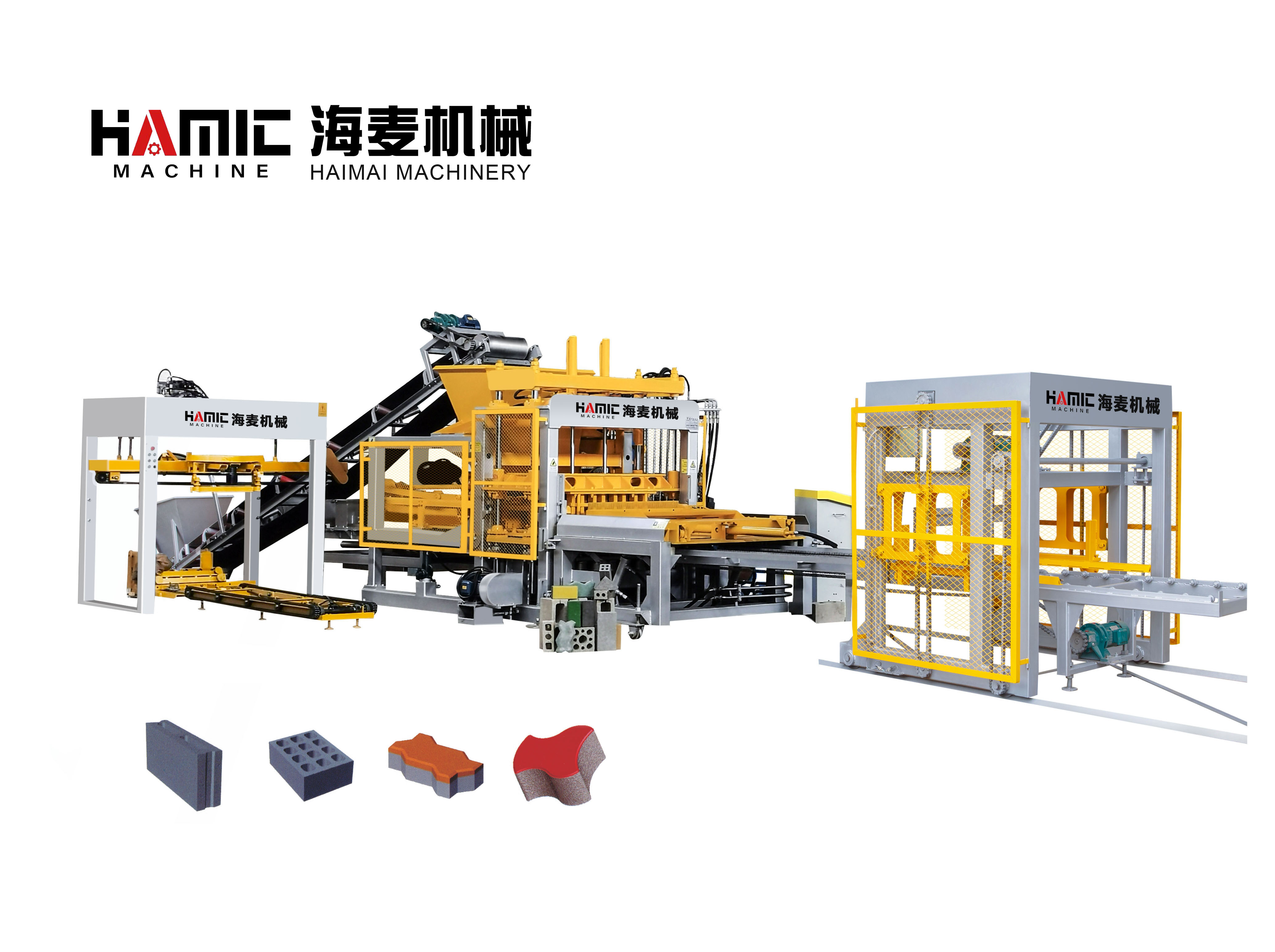

The QT8 Block Making Machine is a game-changer in the construction and manufacturing industries, designed to produce high-quality concrete blocks with speed, precision, and efficiency. Whether you’re a seasoned professional or new to block production, understanding the best practices for using the QT8 can maximize its potential and ensure consistent results.

Features of the QT8 Block Making Machine

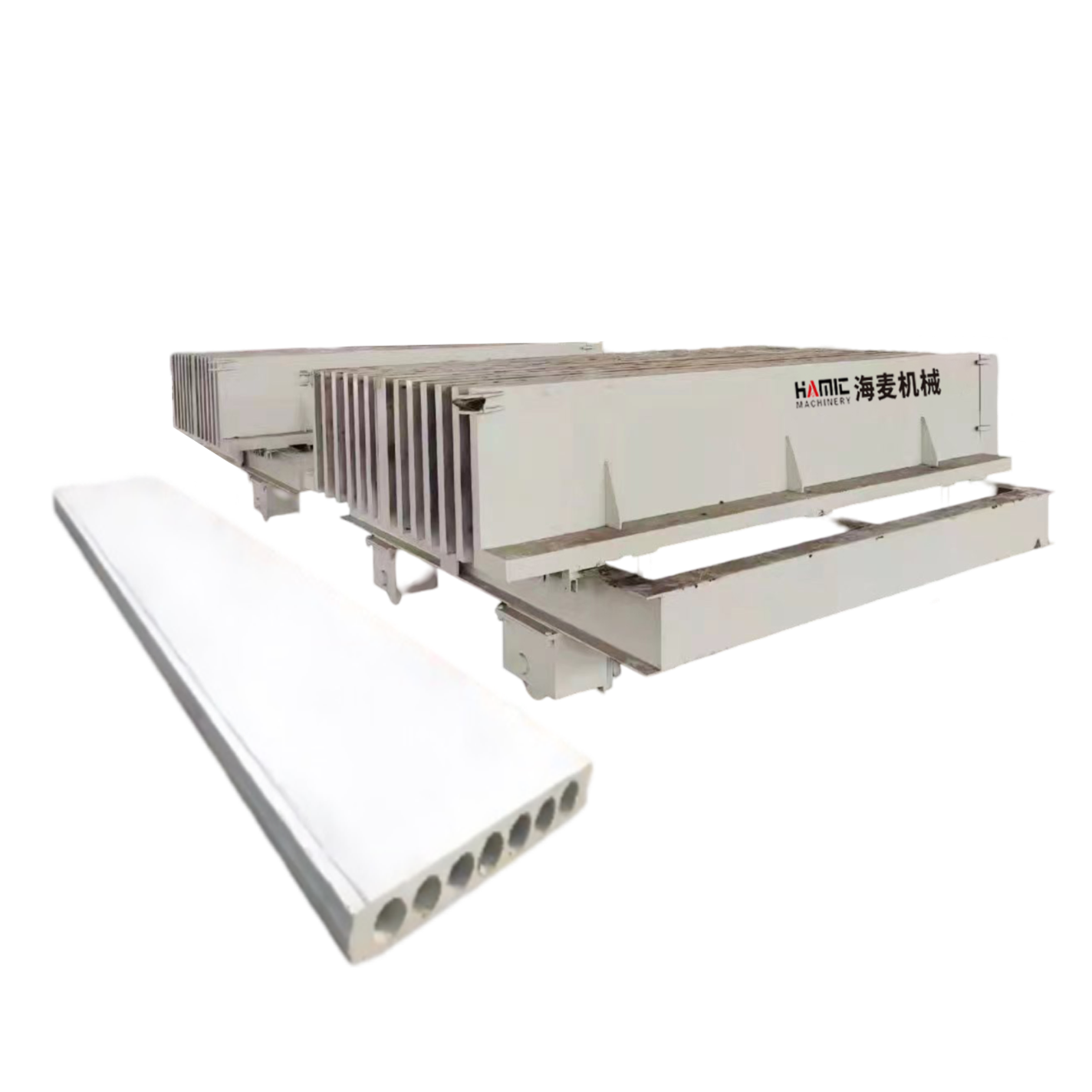

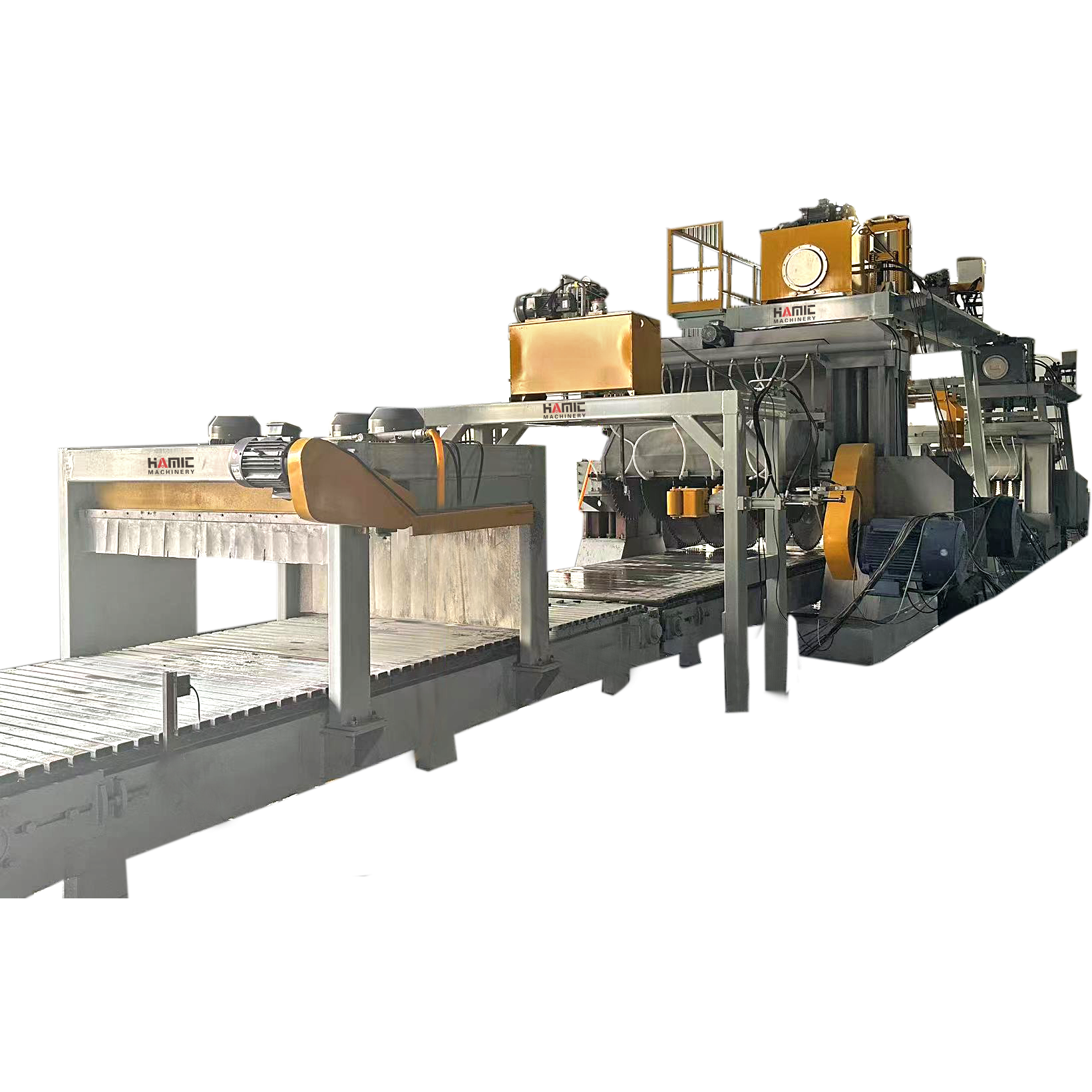

The QT8 Block Making Machine boasts advanced features that set it apart from conventional block-making equipment. It is highly automated, reducing the need for manual intervention and increasing efficiency. With its robust design, the machine is capable of producing a variety of block types, including hollow blocks, solid blocks, and pavers. Its durability ensures long-term use, even in demanding production environments.

Getting Started with the QT8 Block Making Machine

Site Preparation:

Ensure the machine is installed on a flat, stable surface to prevent vibrations during operation. A well-ventilated workspace with ample room for material storage and block curing is ideal.Material Selection:

Use high-quality raw materials, including cement, sand, aggregate, and water, to achieve durable and reliable blocks. The machine's precise mixing system helps maintain the right consistency for optimal results.Machine Setup:

Before starting production, carefully calibrate the machine. Set the mold dimensions and ensure all components, such as the vibration system and hydraulic system, are functioning correctly.Test Run:

Perform a test run to check for potential issues. This ensures the mold fills evenly, and the compaction and vibration mechanisms work as expected.

Maximizing Efficiency During Operation

Maintain a Steady Workflow:

Keep the raw material supply consistent to avoid delays. The QT8’s automated feeding system ensures smooth operation when materials are continuously supplied.Monitor Outputs:

Regularly inspect the finished blocks for uniformity and structural integrity. This helps identify any adjustments needed in the mix ratio or machine settings.Optimize Production Cycles:

Use the machine's customizable settings to adapt to different block designs and sizes. Shorter production cycles can be achieved for simpler block types, increasing overall productivity.

Maintenance Tips for Longevity

Routine Cleaning:

Clean the molds and other components after each production cycle to prevent material buildup, which can affect block quality.Lubrication:

Regularly lubricate moving parts to reduce friction and wear. The hydraulic system also requires periodic oil changes to maintain efficiency.Inspection and Repairs:

Schedule regular inspections to identify and replace worn-out parts. Addressing minor issues promptly can prevent costly repairs down the line.Electrical System Checks:

Ensure all electrical connections are secure and functioning correctly. Faulty wiring can disrupt production or cause safety hazards.

Safety Considerations

- Train all operators thoroughly on the machine's functionality and safety protocols.

- Wear personal protective equipment (PPE), including gloves and safety glasses, to prevent injuries.

- Keep the area around the machine free of obstacles to avoid accidents.

- Use the machine's built-in emergency stop button in case of unexpected malfunctions.

Conclusion

The QT8 Block Making Machine is a versatile and efficient tool for block production, offering high output and consistent quality. By following proper setup procedures, optimizing operations, and maintaining the machine regularly, you can achieve the best results and extend its lifespan. Whether you’re producing blocks for large-scale construction projects or smaller endeavors, the QT8 is designed to meet your needs with precision and reliability.